CNC-Portalfräse: Unterschied zwischen den Versionen

(→Überblick: Neue Erkentinsse über Endtaster und Pinbelegungen) |

K (quick start nach oben, formatierung) |

||

| (69 dazwischenliegende Versionen von 10 Benutzern werden nicht angezeigt) | |||

| Zeile 1: | Zeile 1: | ||

| + | {{Hardware | ||

| + | |kontakt = [[Benutzer:Daniel Bohrer|Daniel Bohrer]], {{Benutzer|Kasalehlia}}, {{Benutzer|larsan}}, {{Benutzer|comawill}}, {{Benutzer|adnc}} | ||

| + | |status = wip | ||

| + | |ort = Werkstatt | ||

| + | |beschreibung = CNC-Fräse | ||

| + | |bild = CNC_mill_meeting.jpg | ||

| + | |bildbeschreibung = erste Inbetriebnahme, noch auf dem Frickelraumtisch | ||

| + | |links = <!--optional--> | ||

| + | |usage = Benutzung erst nach Einweisung. Kaputtmachen und Reparieren nur von Spezialexperten. | ||

| + | }} | ||

| + | |||

{{Hinweis|Diese Seite befindet im Aufbau, es können Platzhalter vorkommen und wichtige Informationen fehlen. Inhaltliche Bearbeitungen und Ergänzungen, sowie Formatierungen sind ausdrücklich erwünscht.}} | {{Hinweis|Diese Seite befindet im Aufbau, es können Platzhalter vorkommen und wichtige Informationen fehlen. Inhaltliche Bearbeitungen und Ergänzungen, sowie Formatierungen sind ausdrücklich erwünscht.}} | ||

Uns wurde am 28.03.2014 eine CNC-Maschine überlassen. Nachdem wir sie unter Verwendung des mitgelieferten Industrierechners ansteuern konnten, stellten wir fest, dass diese Methode nicht viel Zukunft haben würde. Kein USB, beschränkte Geschwindigkeit, laut, Win98 will man nicht im Netzwerk haben, etc. | Uns wurde am 28.03.2014 eine CNC-Maschine überlassen. Nachdem wir sie unter Verwendung des mitgelieferten Industrierechners ansteuern konnten, stellten wir fest, dass diese Methode nicht viel Zukunft haben würde. Kein USB, beschränkte Geschwindigkeit, laut, Win98 will man nicht im Netzwerk haben, etc. | ||

| − | Da die Fräse alle ihre Anschlüsse über D-Sub-Buchsen herausführt, wollen wir einen anderen Controller verwenden, der die Motoren direkt ansteuert. Am 24.05.2014 haben wir mit einem [ | + | Da die Fräse alle ihre Anschlüsse über D-Sub-Buchsen herausführt, wollen wir einen anderen Controller verwenden, der die Motoren direkt ansteuert. Am 24.05.2014 haben wir mit einem [https://smoothieware.github.io/Webif-pack/documentation/web/html/ Smoothieboard] erfolgreich die ersten Schritte in diese Richtung gemacht. |

| + | |||

| + | Stand 27.06.2014: Wir haben uns ein eigenes Smoothieboard 5X zugelegt, das wird derzeit in Betrieb genommen. | ||

| + | |||

| + | == Quick start == | ||

| + | |||

| + | * Web interface: http://192.168.178.222/ | ||

| + | ** Commands: | ||

| + | *** Home: <code>$H</code> | ||

| + | *** Get limit switch state: <code>M119</code> | ||

| + | *** Get position: <code>M114</code> | ||

| + | *** Move back, center, top: <code>G0 F2000 X150 Y405 Z95</code> | ||

| + | * Software [https://github.com/vlachoudis/bCNC bCNC] | ||

| + | ** ''File → Serial → Port'': <code>socket://192.168.178.222:23</code> | ||

| + | ** ''File → Serial → Controller'': ''SMOOTHIE'' | ||

| + | ** ''File → Open'', load GCode file | ||

| + | ** ''File → Pendant → Start'' starts web UI on local port 8080 | ||

== Überblick == | == Überblick == | ||

=== Fräse === | === Fräse === | ||

| − | Es handelt sich um eine etwa 15 | + | [[Datei:CNC-Fräse Holzbalken.jpg|thumb|Durch den Aufbau als Portalfräse ist es möglich, dass Werkstücke in y-Richtung über den Frästisch hinausragen können]] |

| − | Kaum gebraucht und vermutlich seit ~9 Jahren nicht mehr in Betrieb gewesen. | + | |

| − | * Arbeitsbereich: x | + | Es handelt sich um (Stand 2014) eine etwa 15 Jahre alte Isel Automation Flachbett-Tischfräse CNC Multi K. |

| + | Kaum gebraucht und vermutlich seit ~9 Jahren nicht mehr in Betrieb gewesen, bevor sie 2014 zu uns kam. | ||

| + | * maximaler Arbeitsbereich: (x,y,z) = (330 mm, 500 mm, 90 mm), abzüglich Befestigung und eingesetztem Fräser eher so z=70 mm | ||

* Kugelgewindetriebe | * Kugelgewindetriebe | ||

* Zwei Endschalter pro Achse | * Zwei Endschalter pro Achse | ||

* Derzeit zwei Frässpindeln verfügbar | * Derzeit zwei Frässpindeln verfügbar | ||

| − | ** [[ | + | ** <s>[[#HF-Spindel|Hochfrequenzspindel]]</s> defekt, siehe [https://gitli.stratum0.org/stratum0/TUWAT/-/issues/10 TUWAT] |

| − | ** [[ | + | ** [[#Proxxon|Proxxon]] |

| + | ** Kress | ||

* NEMA23 Schrittmotoren der Firma Nanotec [http://de.nanotec.com/fileadmin/files/Datenblaetter/Schrittmotoren/ST5918/ST5918M3008-A.pdf 4T5618M3300] | * NEMA23 Schrittmotoren der Firma Nanotec [http://de.nanotec.com/fileadmin/files/Datenblaetter/Schrittmotoren/ST5918/ST5918M3008-A.pdf 4T5618M3300] | ||

| Zeile 48: | Zeile 78: | ||

* Wird direkt an den Rechner angeschlossen | * Wird direkt an den Rechner angeschlossen | ||

* Mit Aufnahmen für verschiedene Einsatz-Durchmesser bis 3.2 mm | * Mit Aufnahmen für verschiedene Einsatz-Durchmesser bis 3.2 mm | ||

| − | * | + | * Das vordere Lager wurde durch Proxxon kostenlos getauscht und ist somit wieder i.O. |

==== HF-Spindel ==== | ==== HF-Spindel ==== | ||

| Zeile 57: | Zeile 87: | ||

* Siehe Bilder | * Siehe Bilder | ||

| + | * Als Beispiel könnten diese [http://tumblebeer.com/upgrayedd/ Spannpratzen] dienen. | ||

| + | ** Vorstellung von 7 [http://makezine.com/2016/06/20/7-cnc-fixturing-tips-small-shop/ Befestigungsmöglichkeiten] von Werkstücken im CNC-Umfeld. | ||

=== Misc === | === Misc === | ||

| Zeile 66: | Zeile 98: | ||

== Erste Experimente == | == Erste Experimente == | ||

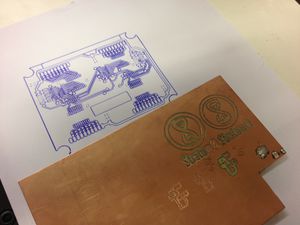

[[Datei:CNC-Experimente.JPG|thumb|Erste CNC Experimente]] | [[Datei:CNC-Experimente.JPG|thumb|Erste CNC Experimente]] | ||

| − | * Anschluss an ein [ | + | * Anschluss an ein [https://smoothieware.github.io/Webif-pack/documentation/web/html/ SmoothieBoard] |

* Config angepasst (Siehe Upload von larsan) | * Config angepasst (Siehe Upload von larsan) | ||

* Mit Eagle und [http://www.pcbgcode.org/ pcb-gcode] gcode erzeugt, auf SmoothieBoard übertragen und ausgeführt | * Mit Eagle und [http://www.pcbgcode.org/ pcb-gcode] gcode erzeugt, auf SmoothieBoard übertragen und ausgeführt | ||

| Zeile 72: | Zeile 104: | ||

=== Smoothieboard config === | === Smoothieboard config === | ||

| + | [[Datei:Smoothieboard 5x new.jpg|thumb|Smoothieboard 5X frisch aus der Verpackung, ohne aufgelötete Kontakte.]] | ||

| + | |||

| + | |||

Eine erste config fürs Smoothieboard, liegt als ''config'' im Rootverzeichnis der µSD-Karte: | Eine erste config fürs Smoothieboard, liegt als ''config'' im Rootverzeichnis der µSD-Karte: | ||

| Zeile 77: | Zeile 112: | ||

# NOTE Lines must not exceed 132 characters | # NOTE Lines must not exceed 132 characters | ||

# Robot module configurations : general handling of movement G-codes and slicing into moves | # Robot module configurations : general handling of movement G-codes and slicing into moves | ||

| − | default_feed_rate | + | default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves |

| − | default_seek_rate | + | default_seek_rate 600 # Default rate ( mm/minute ) for G0 moves |

mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for | mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for | ||

# these segments. Smaller values mean more resolution, | # these segments. Smaller values mean more resolution, | ||

| Zeile 92: | Zeile 127: | ||

# Planner module configuration : Look-ahead and acceleration configuration | # Planner module configuration : Look-ahead and acceleration configuration | ||

planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING | planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING | ||

| − | acceleration | + | acceleration 500 # Acceleration in mm/second/second. |

acceleration_ticks_per_second 1000 # Number of times per second the speed is updated | acceleration_ticks_per_second 1000 # Number of times per second the speed is updated | ||

junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters, | junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters, | ||

| Zeile 107: | Zeile 142: | ||

# Cartesian axis speed limits | # Cartesian axis speed limits | ||

| − | x_axis_max_speed | + | x_axis_max_speed 1500 # mm/min |

| − | y_axis_max_speed | + | y_axis_max_speed 1500 # mm/min |

z_axis_max_speed 300 # mm/min | z_axis_max_speed 300 # mm/min | ||

| Zeile 116: | Zeile 151: | ||

alpha_en_pin 0.4 # Pin for alpha enable pin | alpha_en_pin 0.4 # Pin for alpha enable pin | ||

alpha_current 1.0 # X stepper motor current | alpha_current 1.0 # X stepper motor current | ||

| − | alpha_max_rate | + | alpha_max_rate 1500.0 # mm/min |

beta_step_pin 2.1 # Pin for beta stepper step signal | beta_step_pin 2.1 # Pin for beta stepper step signal | ||

| Zeile 122: | Zeile 157: | ||

beta_en_pin 0.10 # Pin for beta enable | beta_en_pin 0.10 # Pin for beta enable | ||

beta_current 1.0 # Y stepper motor current | beta_current 1.0 # Y stepper motor current | ||

| − | beta_max_rate | + | beta_max_rate 1500.0 # mm/min |

gamma_step_pin 2.2 # Pin for gamma stepper step signal | gamma_step_pin 2.2 # Pin for gamma stepper step signal | ||

| Zeile 268: | Zeile 303: | ||

panel.menu_offset 0 # some panels will need 1 here | panel.menu_offset 0 # some panels will need 1 here | ||

| − | panel.alpha_jog_feedrate | + | panel.alpha_jog_feedrate 1000 # x jogging feedrate in mm/min |

| − | panel.beta_jog_feedrate | + | panel.beta_jog_feedrate 1000 # y jogging feedrate in mm/min |

panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min | panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min | ||

| Zeile 291: | Zeile 326: | ||

# network settings | # network settings | ||

| − | network.enable | + | network.enable true |

| + | # enable the ethernet network services | ||

network.webserver.enable true # enable the webserver | network.webserver.enable true # enable the webserver | ||

network.telnet.enable true # enable the telnet server | network.telnet.enable true # enable the telnet server | ||

| − | network.ip_address auto # use dhcp to get ip address | + | #network.ip_address auto # use dhcp to get ip address |

# uncomment the 3 below to manually setup ip address | # uncomment the 3 below to manually setup ip address | ||

| − | + | network.ip_address 192.168.178.222 # the IP address | |

| − | + | network.ip_mask 255.255.254.0 # the ip mask | |

| − | + | network.ip_gateway 192.168.178.1 # the gateway address | |

#network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict | #network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict | ||

| + | |||

</pre> | </pre> | ||

| − | == | + | Config die am 2023-09-17 vorgefunden wurde: |

| − | + | ||

| + | <pre style="height:200px;overflow-y:scroll;"> | ||

| + | # NOTE Lines must not exceed 132 characters | ||

| + | # Robot module configurations : general handling of movement G-codes and slicing into moves | ||

| + | default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves | ||

| + | default_seek_rate 600 # Default rate ( mm/minute ) for G0 moves | ||

| + | mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for | ||

| + | # these segments. Smaller values mean more resolution, | ||

| + | # higher values mean faster computation | ||

| + | mm_per_line_segment 5 # Lines can be cut into segments ( not usefull with cartesian | ||

| + | # coordinates robots ). | ||

| + | |||

| + | # Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions | ||

| + | alpha_steps_per_mm 800 # Steps per mm for alpha stepper | ||

| + | beta_steps_per_mm 800 # Steps per mm for beta stepper | ||

| + | gamma_steps_per_mm 800 # Steps per mm for gamma stepper | ||

| + | |||

| + | # Planner module configuration : Look-ahead and acceleration configuration | ||

| + | planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING | ||

| + | acceleration 500 # Acceleration in mm/second/second. | ||

| + | acceleration_ticks_per_second 1000 # Number of times per second the speed is updated | ||

| + | junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters, | ||

| + | # see https://github.com/grbl/grbl/blob/master/planner.c#L409 | ||

| + | # and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8 | ||

| + | # Lower values mean being more careful, higher values means being | ||

| + | # faster and have more jerk | ||

| + | #minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec | ||

| + | |||

| + | # Stepper module configuration | ||

| + | microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds | ||

| + | minimum_steps_per_minute 1200 # Never step slower than this | ||

| + | base_stepping_frequency 100000 # Base frequency for stepping, higher gives smoother movement | ||

| + | |||

| + | # Cartesian axis speed limits | ||

| + | x_axis_max_speed 1500 # mm/min | ||

| + | y_axis_max_speed 1500 # mm/min | ||

| + | z_axis_max_speed 300 # mm/min | ||

| + | |||

| + | # Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin ) | ||

| + | alpha_step_pin 2.0 # Pin for alpha stepper step signal | ||

| + | alpha_dir_pin 0.5! # Pin for alpha stepper direction | ||

| + | alpha_en_pin 0.4 # Pin for alpha enable pin | ||

| + | alpha_current 1.0 # X stepper motor current | ||

| + | alpha_max_rate 1500.0 # mm/min | ||

| + | |||

| + | beta_step_pin 2.1 # Pin for beta stepper step signal | ||

| + | beta_dir_pin 0.11 # Pin for beta stepper direction | ||

| + | beta_en_pin 0.10 # Pin for beta enable | ||

| + | beta_current 1.0 # Y stepper motor current | ||

| + | beta_max_rate 1500.0 # mm/min | ||

| + | |||

| + | gamma_step_pin 2.2 # Pin for gamma stepper step signal | ||

| + | gamma_dir_pin 0.20 # Pin for gamma stepper direction | ||

| + | gamma_en_pin 0.19 # Pin for gamma enable | ||

| + | gamma_current 1.0 # Z stepper motor current | ||

| + | gamma_max_rate 300.0 # mm/min | ||

| + | |||

| + | # Serial communications configuration ( baud rate default to 9600 if undefined ) | ||

| + | uart0.baud_rate 115200 # Baud rate for the default hardware serial port | ||

| + | second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface | ||

| + | # and a terminal connected) | ||

| + | #leds_disable true # disable using leds after config loaded | ||

| + | |||

| + | |||

| + | # Extruder module configuration | ||

| + | extruder_module_enable true # Whether to activate the extruder module at all. All configuration | ||

| + | # is ignored if false | ||

| + | extruder_steps_per_mm 140 # Steps per mm for extruder stepper | ||

| + | extruder_default_feed_rate 600 # Default rate ( mm/minute ) for moves where only the extruder moves | ||

| + | extruder_acceleration 500 # Acceleration for retracts, mm/sec^2 | ||

| + | extruder_max_speed 1000 # mm/sec NOTE only used for retracts | ||

| + | |||

| + | extruder_step_pin 2.3 # Pin for extruder step signal | ||

| + | extruder_dir_pin 0.22 # Pin for extruder dir signal | ||

| + | extruder_en_pin 0.21 # Pin for extruder enable signal | ||

| + | delta_current 1.5 # Extruder stepper motor current | ||

| + | |||

| + | # Laser module configuration | ||

| + | laser_module_enable false # Whether to activate the laser module at all. All configuration is | ||

| + | # ignored if false. | ||

| + | #laser_module_pin 2.5 # this pin will be PWMed to control the laser. Only P2.0 - P2.5 | ||

| + | # can be used since laser requires hardware PWM | ||

| + | #laser_module_max_power 0.8 # this is the maximum duty cycle that will be applied to the laser | ||

| + | #laser_module_tickle_power 0.0 # this duty cycle will be used for travel moves to keep the laser | ||

| + | # active without actually burning | ||

| + | #laser_module_pwm_period 20 # this sets the pwm frequency as the period in microseconds | ||

| + | |||

| + | # Hotend temperature control configuration | ||

| + | temperature_control.hotend.enable true # Whether to activate this ( "hotend" ) module at all. | ||

| + | # All configuration is ignored if false. | ||

| + | temperature_control.hotend.thermistor_pin 0.23 # Pin for the thermistor to read | ||

| + | temperature_control.hotend.heater_pin 2.7 # Pin that controls the heater | ||

| + | temperature_control.hotend.thermistor EPCOS100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64 | ||

| + | # for a list of valid thermistor names | ||

| + | temperature_control.hotend.set_m_code 104 # | ||

| + | temperature_control.hotend.set_and_wait_m_code 109 # | ||

| + | temperature_control.hotend.designator T # | ||

| + | |||

| + | #temperature_control.hotend.p_factor 13.7 # permanenetly set the PID values after an auto pid | ||

| + | #temperature_control.hotend.i_factor 0.097 # | ||

| + | #temperature_control.hotend.d_factor 24 # | ||

| + | |||

| + | #temperature_control.hotend.max_pwm 64 # max pwm, 64 is a good value if driving a 12v resistor with 24v. | ||

| + | |||

| + | temperature_control.bed.enable true # | ||

| + | temperature_control.bed.thermistor_pin 0.24 # | ||

| + | temperature_control.bed.heater_pin 2.5 # | ||

| + | temperature_control.bed.thermistor Honeywell100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64 | ||

| + | # for a list of valid thermistor names | ||

| + | temperature_control.bed.set_m_code 140 # | ||

| + | temperature_control.bed.set_and_wait_m_code 190 # | ||

| + | temperature_control.bed.designator B # | ||

| + | |||

| + | #temperature_control.bed.bang_bang false # set to true to use bang bang control rather than PID | ||

| + | #temperature_control.bed.hysteresis 2.0 # set to the temperature in degrees C to use as hysteresis | ||

| + | # when using bang bang | ||

| + | |||

| + | # Switch module for fan control | ||

| + | switch.fan.enable true # | ||

| + | switch.fan.input_on_command M106 # | ||

| + | switch.fan.input_off_command M107 # | ||

| + | switch.fan.output_pin 2.6 # | ||

| + | switch.fan.output_type pwm # pwm output settable with S parameter in the input_on_comand | ||

| + | #switch.fan.max_pwm 255 # set max pwm for the pin default is 255 | ||

| + | |||

| + | #switch.misc.enable true # | ||

| + | #switch.misc.input_on_command M42 # | ||

| + | #switch.misc.input_off_command M43 # | ||

| + | #switch.misc.output_pin 2.4 # | ||

| + | #switch.misc.output_type digital # just an on or off pin | ||

| + | |||

| + | # Switch module for spindle control | ||

| + | #switch.spindle.enable false # | ||

| + | |||

| + | # Endstops | ||

| + | endstops_enable true # the endstop module is enabled by default and can be disabled here | ||

| + | #corexy_homing false # set to true if homing on a hbit or corexy | ||

| + | alpha_min_endstop 1.24^! # add a ! to invert if endstop is NO connected to ground | ||

| + | alpha_max_endstop 1.25^ # | ||

| + | alpha_homing_direction home_to_min # or set to home_to_max and set alpha_max | ||

| + | alpha_min 0 # this gets loaded after homing when home_to_min is set | ||

| + | alpha_max 200 # this gets loaded after homing when home_to_max is set | ||

| + | beta_min_endstop 1.26^! # | ||

| + | beta_max_endstop 1.27^ # | ||

| + | beta_homing_direction home_to_min # | ||

| + | beta_min 0 # | ||

| + | beta_max 200 # | ||

| + | gamma_min_endstop 1.28^! # | ||

| + | gamma_max_endstop 1.29^ # | ||

| + | gamma_homing_direction home_to_min # | ||

| + | gamma_min 0 # | ||

| + | gamma_max 200 # | ||

| + | |||

| + | alpha_fast_homing_rate_mm_s 50 # feedrates in mm/second | ||

| + | beta_fast_homing_rate_mm_s 50 # " | ||

| + | gamma_fast_homing_rate_mm_s 4 # " | ||

| + | alpha_slow_homing_rate_mm_s 25 # " | ||

| + | beta_slow_homing_rate_mm_s 25 # " | ||

| + | gamma_slow_homing_rate_mm_s 2 # " | ||

| + | |||

| + | alpha_homing_retract_mm 5 # distance in mm | ||

| + | beta_homing_retract_mm 5 # " | ||

| + | gamma_homing_retract_mm 1 # " | ||

| + | |||

| + | #endstop_debounce_count 100 # uncomment if you get noise on your endstops | ||

| + | |||

| + | # Pause button | ||

| + | pause_button_enable true # | ||

| + | |||

| + | # Panel | ||

| + | panel.enable true # set to true to enable the panel code | ||

| + | panel.encoder_a_pin 3.25!^ # encoder pin | ||

| + | panel.encoder_b_pin 3.26!^ # encoder pin | ||

| + | |||

| + | # Example for reprap discount GLCD | ||

| + | # on glcd EXP1 is to left and EXP2 is to right, pin 1 is bottom left, pin 2 is top left etc. | ||

| + | # +5v is EXP1 pin 10, Gnd is EXP1 pin 9 | ||

| + | panel.lcd universal_adapter # | ||

| + | panel.spi_channel 0 # spi channel to use ; GLCD EXP1 Pins 3,5 (MOSI, SCLK) | ||

| + | panel.spi_cs_pin 0.16 # spi chip select ; GLCD EXP1 Pin 4 | ||

| + | #panel.encoder_a_pin 3.25!^ # encoder pin ; GLCD EXP2 Pin 3 | ||

| + | #panel.encoder_b_pin 3.26!^ # encoder pin ; GLCD EXP2 Pin 5 | ||

| + | #panel.click_button_pin 1.30!^ # click button ; GLCD EXP1 Pin 2 | ||

| + | #panel.buzz_pin 1.31 # pin for buzzer ; GLCD EXP1 Pin 1 | ||

| + | #panel.button_pause_pin 2.11^ # kill/pause ; GLCD EXP2 Pin 8 either | ||

| + | #panel.back_button_pin 2.11!^ # back button ; GLCD EXP2 Pin 8 or | ||

| + | |||

| + | # pins used with other panels | ||

| + | #panel.up_button_pin 0.1! # up button if used | ||

| + | #panel.down_button_pin 0.0! # down button if used | ||

| + | #panel.click_button_pin 0.18! # click button if used | ||

| + | |||

| + | panel.menu_offset 0 # some panels will need 1 here | ||

| + | |||

| + | panel.alpha_jog_feedrate 1000 # x jogging feedrate in mm/min | ||

| + | panel.beta_jog_feedrate 1000 # y jogging feedrate in mm/min | ||

| + | panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min | ||

| + | |||

| + | #panel.hotend_temperature 185 # temp to set hotend when preheat is selected | ||

| + | #panel.bed_temperature 60 # temp to set bed when preheat is selected | ||

| + | |||

| + | # Example of a custom menu entry, which will show up in the Custom entry. | ||

| + | # NOTE _ gets converted to space in the menu and commands, | is used to separate multiple commands | ||

| + | custom_menu.power_on.enable true # | ||

| + | custom_menu.power_on.name Power_on # | ||

| + | custom_menu.power_on.command M80 # | ||

| + | |||

| + | custom_menu.power_off.enable true # | ||

| + | custom_menu.power_off.name Power_off # | ||

| + | custom_menu.power_off.command M81 # | ||

| + | |||

| + | # Only needed on a smoothieboard | ||

| + | currentcontrol_module_enable true # | ||

| + | |||

| + | return_error_on_unhandled_gcode false # | ||

| + | |||

| + | # network settings | ||

| + | network.enable true | ||

| + | # enable the ethernet network services | ||

| + | network.webserver.enable true # enable the webserver | ||

| + | network.telnet.enable true # enable the telnet server | ||

| + | #network.ip_address auto # use dhcp to get ip address | ||

| + | # uncomment the 3 below to manually setup ip address | ||

| + | network.ip_address 192.168.178.222 # the IP address | ||

| + | network.ip_mask 255.255.254.0 # the ip mask | ||

| + | network.ip_gateway 192.168.178.1 # the gateway address | ||

| + | #network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict | ||

| + | # | ||

| + | # | ||

| + | # | ||

| + | </pre> | ||

| + | |||

| + | |||

| + | Configuration after adding support for auto-homing on 2023-09-17 | ||

| + | <pre style="height:200px;overflow-y:scroll;"> | ||

| + | # NOTE Lines must not exceed 132 characters | ||

| + | # Robot module configurations : general handling of movement G-codes and slicing into moves | ||

| + | default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves | ||

| + | default_seek_rate 1500 # Default rate ( mm/minute ) for G0 moves | ||

| + | mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for | ||

| + | # these segments. Smaller values mean more resolution, | ||

| + | # higher values mean faster computation | ||

| + | mm_per_line_segment 5 # Lines can be cut into segments ( not usefull with cartesian | ||

| + | # coordinates robots ). | ||

| + | |||

| + | # Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions | ||

| + | alpha_steps_per_mm 800 # Steps per mm for alpha stepper | ||

| + | beta_steps_per_mm 800 # Steps per mm for beta stepper | ||

| + | gamma_steps_per_mm 800 # Steps per mm for gamma stepper | ||

| + | |||

| + | # Planner module configuration : Look-ahead and acceleration configuration | ||

| + | planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING | ||

| + | acceleration 500 # Acceleration in mm/second/second. | ||

| + | acceleration_ticks_per_second 1000 # Number of times per second the speed is updated | ||

| + | junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters, | ||

| + | # see https://github.com/grbl/grbl/blob/master/planner.c#L409 | ||

| + | # and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8 | ||

| + | # Lower values mean being more careful, higher values means being | ||

| + | # faster and have more jerk | ||

| + | #minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec | ||

| + | |||

| + | # Stepper module configuration | ||

| + | microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds | ||

| + | minimum_steps_per_minute 1200 # Never step slower than this | ||

| + | base_stepping_frequency 100000 # Base frequency for stepping, higher gives smoother movement | ||

| + | |||

| + | # Cartesian axis speed limits | ||

| + | x_axis_max_speed 2000 # mm/min | ||

| + | y_axis_max_speed 2000 # mm/min | ||

| + | z_axis_max_speed 1000 # mm/min | ||

| + | |||

| + | # Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin ) | ||

| + | alpha_step_pin 2.0 # Pin for alpha stepper step signal | ||

| + | alpha_dir_pin 0.5! # Pin for alpha stepper direction | ||

| + | alpha_en_pin 0.4 # Pin for alpha enable pin | ||

| + | alpha_current 1.0 # X stepper motor current | ||

| + | alpha_max_rate 2000.0 # mm/min | ||

| + | |||

| + | beta_step_pin 2.1 # Pin for beta stepper step signal | ||

| + | beta_dir_pin 0.11 # Pin for beta stepper direction | ||

| + | beta_en_pin 0.10 # Pin for beta enable | ||

| + | beta_current 1.5 # Y stepper motor current | ||

| + | beta_max_rate 2000.0 # mm/min | ||

| + | |||

| + | gamma_step_pin 2.2 # Pin for gamma stepper step signal | ||

| + | gamma_dir_pin 0.20 # Pin for gamma stepper direction | ||

| + | gamma_en_pin 0.19 # Pin for gamma enable | ||

| + | gamma_current 1.0 # Z stepper motor current | ||

| + | gamma_max_rate 1000.0 # mm/min | ||

| + | |||

| + | # Serial communications configuration ( baud rate default to 9600 if undefined ) | ||

| + | uart0.baud_rate 115200 # Baud rate for the default hardware serial port | ||

| + | second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface | ||

| + | # and a terminal connected) | ||

| + | #leds_disable true # disable using leds after config loaded | ||

| + | |||

| + | |||

| + | # Extruder module configuration | ||

| + | extruder_module_enable false # Whether to activate the extruder module at all. All configuration | ||

| + | # is ignored if false | ||

| + | |||

| + | # Laser module configuration | ||

| + | laser_module_enable false # Whether to activate the laser module at all. All configuration is | ||

| + | # ignored if false. | ||

| + | #laser_module_pin 2.5 # this pin will be PWMed to control the laser. Only P2.0 - P2.5 | ||

| + | # can be used since laser requires hardware PWM | ||

| + | #laser_module_max_power 0.8 # this is the maximum duty cycle that will be applied to the laser | ||

| + | #laser_module_tickle_power 0.0 # this duty cycle will be used for travel moves to keep the laser | ||

| + | # active without actually burning | ||

| + | #laser_module_pwm_period 20 # this sets the pwm frequency as the period in microseconds | ||

| + | |||

| + | # Hotend temperature control configuration | ||

| + | temperature_control.hotend.enable false # Whether to activate this ( "hotend" ) module at all. | ||

| + | # All configuration is ignored if false. | ||

| + | temperature_control.bed.enable false # | ||

| − | + | # Switch module for fan control | |

| + | switch.fan.enable false # | ||

| − | + | # Switch module for spindle control | |

| − | + | #switch.spindle.enable false # | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | # Endstops | |

| − | + | endstops_enable true # the endstop module is enabled by default and can be disabled here | |

| + | #corexy_homing false # set to true if homing on a hbit or corexy | ||

| + | alpha_min_endstop 1.24^ # add a ! to invert if endstop is NO connected to ground | ||

| + | alpha_max_endstop 1.25^ # | ||

| + | alpha_homing_direction home_to_min # or set to home_to_max and set alpha_max | ||

| + | alpha_min 0 # this gets loaded after homing when home_to_min is set | ||

| + | alpha_max 200 # this gets loaded after homing when home_to_max is set | ||

| + | alpha_limit_enable false | ||

| + | beta_min_endstop 1.26^ # | ||

| + | beta_max_endstop 1.27^ # | ||

| + | beta_homing_direction home_to_min # | ||

| + | beta_min 0 # | ||

| + | beta_max 200 # | ||

| + | beta_limit_enable false | ||

| + | gamma_min_endstop 1.28^ # | ||

| + | gamma_max_endstop 1.29^ # | ||

| + | gamma_homing_direction home_to_max # | ||

| + | gamma_min 0 # | ||

| + | gamma_max 100 # | ||

| + | gamma_limit_enable false | ||

| − | + | alpha_fast_homing_rate_mm_s 100 # feedrates in mm/second | |

| − | + | beta_fast_homing_rate_mm_s 100 # " | |

| − | + | gamma_fast_homing_rate_mm_s 20 # " | |

| − | + | alpha_slow_homing_rate_mm_s 25 # " | |

| + | beta_slow_homing_rate_mm_s 25 # " | ||

| + | gamma_slow_homing_rate_mm_s 2 # " | ||

| − | + | alpha_homing_retract_mm 5 # distance in mm | |

| − | + | beta_homing_retract_mm 5 # " | |

| + | gamma_homing_retract_mm 1 # " | ||

| − | + | home_z_first true | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | #endstop_debounce_count 100 # uncomment if you get noise on your endstops | |

| − | |||

| − | |||

| + | # Pause button | ||

| + | pause_button_enable true # | ||

| − | + | # Only needed on a smoothieboard | |

| − | + | currentcontrol_module_enable true # | |

| − | + | return_error_on_unhandled_gcode false # | |

| − | http://www- | + | # network settings |

| + | network.enable true | ||

| + | # enable the ethernet network services | ||

| + | network.webserver.enable true # enable the webserver | ||

| + | network.telnet.enable true # enable the telnet server | ||

| + | #network.ip_address auto # use dhcp to get ip address | ||

| + | # uncomment the 3 below to manually setup ip address | ||

| + | network.ip_address 192.168.178.222 # the IP address | ||

| + | network.ip_mask 255.255.254.0 # the ip mask | ||

| + | network.ip_gateway 192.168.178.1 # the gateway address | ||

| + | #network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict | ||

| + | </pre> | ||

| + | |||

| + | == Workflow == | ||

| + | # '''Model (CAD)''' | ||

| + | #* Erzeugen des Models mittels einer CAD-Software. | ||

| + | #** 3D | ||

| + | #*** [http://freecadweb.org/ FreeCAD] | ||

| + | #*** [http://librecad.org/ LibreCAD] | ||

| + | #*** [http://www.openscad.org/ OpenSCAD] | ||

| + | #*** [http://www.blender.org/ Blender] | ||

| + | #*** [https://www.autodesk.com/products/fusion-360/overview Fusion 360] - [[CNC-Fräse/Fusion360|installiert auf Stratux]] | ||

| + | #** 2D | ||

| + | #*** [http://www.qcad.org/ QCAD] | ||

| + | #*** [http://www.openscad.org/ OpenSCAD] | ||

| + | #*** [http://www.inkscape.org/ Inkscape] | ||

| + | # '''Fräsanweisungen (CAM)''' | ||

| + | #: Erzeugen der Fräsanweisungen/Maschinenanweisungen mit einer CAM. | ||

| + | #: Wir suchen noch nach einer brauchbaren Open-Source Lösung. | ||

| + | #* [http://www.cambam.info/ CamBam] (kommerziell, Windows): Es gibt eine ältere Mono Version für Linux. Die Demo schneidet nach 40 mal Starten Gcode ab. | ||

| + | #**CamBam ist auf [[Stratux]] installiert | ||

| + | #* [https://wiki.freecadweb.org/Path_Workbench FreeCAD mit Path Workbench] ([[Vorträge/Vorbei#Talks am Samstag, 14. August 2021, ab 19:00 (online)|Vortrag]] dazu) | ||

| + | #* [http://pycam.sourceforge.net/ PyCAM] (open source, plattformunabhängig): Sieht im Vergleich zu aktuellen kommerziellen Lösungen alt aus und ist bisweilen recht langsam. | ||

| + | #* [https://github.com/Heeks/heekscad HeeksCAD] (open source, Windows/Linux): | ||

| + | #* [http://cam.autodesk.de/inventor-hsm/ Inventor HSM] (kommerziell, Windows 64bit): Gibt für Studenten eine 3-Jahres Lizenz kostenlos, aber mit viel DRM. | ||

| + | #* [http://flatcam.org/ FlatCam] Tool zur Generierung von Maschinencode für das [[CNC-Fräse/Isolationsfräsen]]. | ||

| + | #* [http://jscut.org/ jscut], SVG nach GCode, läuft im Browser, [https://github.com/tbfleming/jscut Open Source auf GitHub] | ||

| + | #* [https://inkscape.org Inkscape] mit GCodetools-Plugin ([https://www.norwegiancreations.com/2015/08/an-intro-to-g-code-and-how-to-generate-it-using-inkscape/ Tutorial]) | ||

| + | #* [https://github.com/stratum0/CNCmilling Eigenbau by Drahflow] Python-Script für Umwandlung von Tiefenkarten in G-Code. | ||

| + | # '''Simulation''' | ||

| + | #* Eine Simulation der Fräsanweisungen kann bei Bedarf mit [http://camotics.org/ CAMotics] durchgeführt werden | ||

| + | #* Kleinere G-Code Dateien simuliert auch http://nraynaud.github.io/webgcode/ | ||

| + | # '''Übertragen auf CNC-Controller Smoothieboard''' | ||

| + | #* Per Dateiupload (Datenträger von Smoothieboard, SD-Karte) [http://192.168.178.222 SmoothieControl] | ||

| + | #** notfalls kann man das SmoothieBoard auch über USB mit dem Befehl <code>net</code> in Pronterface oder über die serielle Konsole nach seiner IP-Adresse fragen | ||

| + | # '''Koordinatensystem der Fräse setzen''' | ||

| + | #*Fräse per Smoothie WebApp auf den gewünschten Nullpunkt fahren | ||

| + | #*per Webapp den G-Code "G92 X0 Y0 Z0" senden (Setzt aktuelle Position als X:0, Y:0, Z:0 im globalen Koordinatensystem.) | ||

| + | # '''Fräsen''' | ||

| + | === Parameter für verschiedene Werkstoffe === | ||

| + | Parameter finden sich sind auf der Unterseite [[CNC-Fräse/Parameter]] | ||

| − | == | + | == Steuern des Smoothieboards == |

| − | * | + | * Per seriell Verbindung über Konsole "screen /dev/ttyACM0 115200", oder Pronterface GUI |

| − | * | + | * Per Netzwerkverbindung über Konsole mit Telnet, oder Http Web UI |

| − | * | + | * Mittlerweile existiert sogar eine Android App [https://gitlab.com/damfle/SmoothieControl SmoothieControl] |

| − | |||

| − | |||

| − | |||

| − | |||

| + | * [https://github.com/vlachoudis/bCNC bCNC] ermöglicht das Senden von GCODE-Anweisungen und Visualisierung der Fräsbahnen in einer GUI. | ||

| + | == Weblinks == | ||

| + | * [https://smoothieware.github.io/Webif-pack/documentation/web/html/ Smoothieboard Projektwebseite] | ||

| + | * [http://en.wikipedia.org/wiki/G-code GCodes (allgemein)] | ||

| + | * [http://reprap.org/wiki/G-code GCodes (reprap)] | ||

| + | * [https://smoothieware.github.io/Webif-pack/documentation/web/html/supported-g-codes.html Vom Smoothieboard unterstützte GCodes (unvollständig)] | ||

[[Kategorie:Infrastruktur]] | [[Kategorie:Infrastruktur]] | ||

| − | [[Kategorie: | + | [[Kategorie:CNC-Fräse]] |

Aktuelle Version vom 23. April 2024, 22:36 Uhr

| CNC-Portalfräse | |

|---|---|

erste Inbetriebnahme, noch auf dem Frickelraumtisch | |

| Beschreibung: | CNC-Fräse |

| Ort: | Werkstatt |

| Status: | work in progress (Was heißt das?) |

| Kontakt: | Daniel Bohrer, Kasalehlia, larsan, comawill, adnc |

| Usage Policy: | Benutzung erst nach Einweisung. Kaputtmachen und Reparieren nur von Spezialexperten. |

Diese Seite befindet im Aufbau, es können Platzhalter vorkommen und wichtige Informationen fehlen. Inhaltliche Bearbeitungen und Ergänzungen, sowie Formatierungen sind ausdrücklich erwünscht.

Uns wurde am 28.03.2014 eine CNC-Maschine überlassen. Nachdem wir sie unter Verwendung des mitgelieferten Industrierechners ansteuern konnten, stellten wir fest, dass diese Methode nicht viel Zukunft haben würde. Kein USB, beschränkte Geschwindigkeit, laut, Win98 will man nicht im Netzwerk haben, etc.

Da die Fräse alle ihre Anschlüsse über D-Sub-Buchsen herausführt, wollen wir einen anderen Controller verwenden, der die Motoren direkt ansteuert. Am 24.05.2014 haben wir mit einem Smoothieboard erfolgreich die ersten Schritte in diese Richtung gemacht.

Stand 27.06.2014: Wir haben uns ein eigenes Smoothieboard 5X zugelegt, das wird derzeit in Betrieb genommen.

Inhaltsverzeichnis

Quick start

- Web interface: http://192.168.178.222/

- Commands:

- Home:

$H - Get limit switch state:

M119 - Get position:

M114 - Move back, center, top:

G0 F2000 X150 Y405 Z95

- Home:

- Commands:

- Software bCNC

- File → Serial → Port:

socket://192.168.178.222:23 - File → Serial → Controller: SMOOTHIE

- File → Open, load GCode file

- File → Pendant → Start starts web UI on local port 8080

- File → Serial → Port:

Überblick

Fräse

Es handelt sich um (Stand 2014) eine etwa 15 Jahre alte Isel Automation Flachbett-Tischfräse CNC Multi K. Kaum gebraucht und vermutlich seit ~9 Jahren nicht mehr in Betrieb gewesen, bevor sie 2014 zu uns kam.

- maximaler Arbeitsbereich: (x,y,z) = (330 mm, 500 mm, 90 mm), abzüglich Befestigung und eingesetztem Fräser eher so z=70 mm

- Kugelgewindetriebe

- Zwei Endschalter pro Achse

- Derzeit zwei Frässpindeln verfügbar

Hochfrequenzspindeldefekt, siehe TUWAT- Proxxon

- Kress

- NEMA23 Schrittmotoren der Firma Nanotec 4T5618M3300

Motoranschlüsse an der Fräse

Die Fräse führt an der Hinterseite 3 D-Sub DE-9 Buchsen heraus, die je für die Ansteuerung der X-, Y- und Z-Achse zwei Polepaaranschlüsse bereitstellt. Pinbelegung D-Sub DE-9 Buchsen

1. Pol A 2. Pol /A 3. Pol B 4. Pol /B 5. 6. 7. 8. 9.

In der Fräse selbst steckt keine Logik, die Achsen werden über drei D-Sub-Buchsen aus der Fräse herausgeführt.

Endschalter

- X-Achse: Endschalter für min. und max. sind vorhanden

- Y-Achse: Endschalter für min. und max. sind vorhanden

- Z-Achse: Endschalter für min. und max. sind vorhanden

Die Entschalter mit NC (Normally Connected) an den jeweiligen D-Sub DE-9 Buchsen mit den Pins 5 (Common), 7 und 9 angeschlossen. Auf dem 25-Pol Kabel ist allerdings Pin 9 Common. Das sollte sich durch umlöten der Stecker an der CNC-Fräse aber ändern lassen.

Werkzeuge

Proxxon

- 230V, 100W

- 20k 1/min direkt am Gerät stufenlos verstellbar

- Wird direkt an den Rechner angeschlossen

- Mit Aufnahmen für verschiedene Einsatz-Durchmesser bis 3.2 mm

- Das vordere Lager wurde durch Proxxon kostenlos getauscht und ist somit wieder i.O.

HF-Spindel

- Wird von einem externen Netzteil mit Strom versorgt, das wiederum über "Fußpedal"-Anschluss mit Rechner ("HF-Spindel") verbunden wird. (Kann kurzgeschlossen werden, die Spindel ohne den Rechner zu betreiben.

- 50k 1/min

Werkzeug-Einsätze

- Siehe Bilder

- Als Beispiel könnten diese Spannpratzen dienen.

- Vorstellung von 7 Befestigungsmöglichkeiten von Werkstücken im CNC-Umfeld.

Misc

- Produktnr. 148508

- Ident 9911 00042

Erste Experimente

- Anschluss an ein SmoothieBoard

- Config angepasst (Siehe Upload von larsan)

- Mit Eagle und pcb-gcode gcode erzeugt, auf SmoothieBoard übertragen und ausgeführt

- Noch einige Probleme mit der Einstellung der Höhe(Z-Achse), da der Kleber unter der Platine etwas uneben war

Smoothieboard config

Eine erste config fürs Smoothieboard, liegt als config im Rootverzeichnis der µSD-Karte:

# NOTE Lines must not exceed 132 characters

# Robot module configurations : general handling of movement G-codes and slicing into moves

default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves

default_seek_rate 600 # Default rate ( mm/minute ) for G0 moves

mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for

# these segments. Smaller values mean more resolution,

# higher values mean faster computation

mm_per_line_segment 5 # Lines can be cut into segments ( not usefull with cartesian

# coordinates robots ).

# Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions

alpha_steps_per_mm 800 # Steps per mm for alpha stepper

beta_steps_per_mm 800 # Steps per mm for beta stepper

gamma_steps_per_mm 800 # Steps per mm for gamma stepper

# Planner module configuration : Look-ahead and acceleration configuration

planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING

acceleration 500 # Acceleration in mm/second/second.

acceleration_ticks_per_second 1000 # Number of times per second the speed is updated

junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters,

# see https://github.com/grbl/grbl/blob/master/planner.c#L409

# and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8

# Lower values mean being more careful, higher values means being

# faster and have more jerk

#minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec

# Stepper module configuration

microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds

minimum_steps_per_minute 1200 # Never step slower than this

base_stepping_frequency 100000 # Base frequency for stepping, higher gives smoother movement

# Cartesian axis speed limits

x_axis_max_speed 1500 # mm/min

y_axis_max_speed 1500 # mm/min

z_axis_max_speed 300 # mm/min

# Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin )

alpha_step_pin 2.0 # Pin for alpha stepper step signal

alpha_dir_pin 0.5 # Pin for alpha stepper direction

alpha_en_pin 0.4 # Pin for alpha enable pin

alpha_current 1.0 # X stepper motor current

alpha_max_rate 1500.0 # mm/min

beta_step_pin 2.1 # Pin for beta stepper step signal

beta_dir_pin 0.11 # Pin for beta stepper direction

beta_en_pin 0.10 # Pin for beta enable

beta_current 1.0 # Y stepper motor current

beta_max_rate 1500.0 # mm/min

gamma_step_pin 2.2 # Pin for gamma stepper step signal

gamma_dir_pin 0.20 # Pin for gamma stepper direction

gamma_en_pin 0.19 # Pin for gamma enable

gamma_current 1.0 # Z stepper motor current

gamma_max_rate 300.0 # mm/min

# Serial communications configuration ( baud rate default to 9600 if undefined )

uart0.baud_rate 115200 # Baud rate for the default hardware serial port

second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface

# and a terminal connected)

#leds_disable true # disable using leds after config loaded

# Extruder module configuration

extruder_module_enable true # Whether to activate the extruder module at all. All configuration

# is ignored if false

extruder_steps_per_mm 140 # Steps per mm for extruder stepper

extruder_default_feed_rate 600 # Default rate ( mm/minute ) for moves where only the extruder moves

extruder_acceleration 500 # Acceleration for retracts, mm/sec^2

extruder_max_speed 1000 # mm/sec NOTE only used for retracts

extruder_step_pin 2.3 # Pin for extruder step signal

extruder_dir_pin 0.22 # Pin for extruder dir signal

extruder_en_pin 0.21 # Pin for extruder enable signal

delta_current 1.5 # Extruder stepper motor current

# Laser module configuration

laser_module_enable false # Whether to activate the laser module at all. All configuration is

# ignored if false.

#laser_module_pin 2.5 # this pin will be PWMed to control the laser. Only P2.0 - P2.5

# can be used since laser requires hardware PWM

#laser_module_max_power 0.8 # this is the maximum duty cycle that will be applied to the laser

#laser_module_tickle_power 0.0 # this duty cycle will be used for travel moves to keep the laser

# active without actually burning

#laser_module_pwm_period 20 # this sets the pwm frequency as the period in microseconds

# Hotend temperature control configuration

temperature_control.hotend.enable true # Whether to activate this ( "hotend" ) module at all.

# All configuration is ignored if false.

temperature_control.hotend.thermistor_pin 0.23 # Pin for the thermistor to read

temperature_control.hotend.heater_pin 2.7 # Pin that controls the heater

temperature_control.hotend.thermistor EPCOS100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64

# for a list of valid thermistor names

temperature_control.hotend.set_m_code 104 #

temperature_control.hotend.set_and_wait_m_code 109 #

temperature_control.hotend.designator T #

#temperature_control.hotend.p_factor 13.7 # permanenetly set the PID values after an auto pid

#temperature_control.hotend.i_factor 0.097 #

#temperature_control.hotend.d_factor 24 #

#temperature_control.hotend.max_pwm 64 # max pwm, 64 is a good value if driving a 12v resistor with 24v.

temperature_control.bed.enable true #

temperature_control.bed.thermistor_pin 0.24 #

temperature_control.bed.heater_pin 2.5 #

temperature_control.bed.thermistor Honeywell100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64

# for a list of valid thermistor names

temperature_control.bed.set_m_code 140 #

temperature_control.bed.set_and_wait_m_code 190 #

temperature_control.bed.designator B #

#temperature_control.bed.bang_bang false # set to true to use bang bang control rather than PID

#temperature_control.bed.hysteresis 2.0 # set to the temperature in degrees C to use as hysteresis

# when using bang bang

# Switch module for fan control

switch.fan.enable true #

switch.fan.input_on_command M106 #

switch.fan.input_off_command M107 #

switch.fan.output_pin 2.6 #

switch.fan.output_type pwm # pwm output settable with S parameter in the input_on_comand

#switch.fan.max_pwm 255 # set max pwm for the pin default is 255

#switch.misc.enable true #

#switch.misc.input_on_command M42 #

#switch.misc.input_off_command M43 #

#switch.misc.output_pin 2.4 #

#switch.misc.output_type digital # just an on or off pin

# Switch module for spindle control

#switch.spindle.enable false #

# Endstops

endstops_enable true # the endstop module is enabled by default and can be disabled here

#corexy_homing false # set to true if homing on a hbit or corexy

alpha_min_endstop 1.24^ # add a ! to invert if endstop is NO connected to ground

alpha_max_endstop 1.25^ #

alpha_homing_direction home_to_min # or set to home_to_max and set alpha_max

alpha_min 0 # this gets loaded after homing when home_to_min is set

alpha_max 200 # this gets loaded after homing when home_to_max is set

beta_min_endstop 1.26^ #

beta_max_endstop 1.27^ #

beta_homing_direction home_to_min #

beta_min 0 #

beta_max 200 #

gamma_min_endstop 1.28^ #

gamma_max_endstop 1.29^ #

gamma_homing_direction home_to_min #

gamma_min 0 #

gamma_max 200 #

alpha_fast_homing_rate_mm_s 50 # feedrates in mm/second

beta_fast_homing_rate_mm_s 50 # "

gamma_fast_homing_rate_mm_s 4 # "

alpha_slow_homing_rate_mm_s 25 # "

beta_slow_homing_rate_mm_s 25 # "

gamma_slow_homing_rate_mm_s 2 # "

alpha_homing_retract_mm 5 # distance in mm

beta_homing_retract_mm 5 # "

gamma_homing_retract_mm 1 # "

#endstop_debounce_count 100 # uncomment if you get noise on your endstops

# Pause button

pause_button_enable true #

# Panel

panel.enable false # set to true to enable the panel code

panel.lcd smoothiepanel # set type of panel

panel.encoder_a_pin 3.25!^ # encoder pin

panel.encoder_b_pin 3.26!^ # encoder pin

# Example for reprap discount GLCD

# on glcd EXP1 is to left and EXP2 is to right, pin 1 is bottom left, pin 2 is top left etc.

# +5v is EXP1 pin 10, Gnd is EXP1 pin 9

#panel.lcd reprap_discount_glcd #

#panel.spi_channel 0 # spi channel to use ; GLCD EXP1 Pins 3,5 (MOSI, SCLK)

#panel.spi_cs_pin 0.16 # spi chip select ; GLCD EXP1 Pin 4

#panel.encoder_a_pin 3.25!^ # encoder pin ; GLCD EXP2 Pin 3

#panel.encoder_b_pin 3.26!^ # encoder pin ; GLCD EXP2 Pin 5

#panel.click_button_pin 1.30!^ # click button ; GLCD EXP1 Pin 2

#panel.buzz_pin 1.31 # pin for buzzer ; GLCD EXP1 Pin 1

#panel.button_pause_pin 2.11^ # kill/pause ; GLCD EXP2 Pin 8 either

#panel.back_button_pin 2.11!^ # back button ; GLCD EXP2 Pin 8 or

# pins used with other panels

#panel.up_button_pin 0.1! # up button if used

#panel.down_button_pin 0.0! # down button if used

#panel.click_button_pin 0.18! # click button if used

panel.menu_offset 0 # some panels will need 1 here

panel.alpha_jog_feedrate 1000 # x jogging feedrate in mm/min

panel.beta_jog_feedrate 1000 # y jogging feedrate in mm/min

panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min

panel.hotend_temperature 185 # temp to set hotend when preheat is selected

panel.bed_temperature 60 # temp to set bed when preheat is selected

# Example of a custom menu entry, which will show up in the Custom entry.

# NOTE _ gets converted to space in the menu and commands, | is used to separate multiple commands

custom_menu.power_on.enable true #

custom_menu.power_on.name Power_on #

custom_menu.power_on.command M80 #

custom_menu.power_off.enable true #

custom_menu.power_off.name Power_off #

custom_menu.power_off.command M81 #

# Only needed on a smoothieboard

currentcontrol_module_enable true #

return_error_on_unhandled_gcode false #

# network settings

network.enable true

# enable the ethernet network services

network.webserver.enable true # enable the webserver

network.telnet.enable true # enable the telnet server

#network.ip_address auto # use dhcp to get ip address

# uncomment the 3 below to manually setup ip address

network.ip_address 192.168.178.222 # the IP address

network.ip_mask 255.255.254.0 # the ip mask

network.ip_gateway 192.168.178.1 # the gateway address

#network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict

Config die am 2023-09-17 vorgefunden wurde:

# NOTE Lines must not exceed 132 characters

# Robot module configurations : general handling of movement G-codes and slicing into moves

default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves

default_seek_rate 600 # Default rate ( mm/minute ) for G0 moves

mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for

# these segments. Smaller values mean more resolution,

# higher values mean faster computation

mm_per_line_segment 5 # Lines can be cut into segments ( not usefull with cartesian

# coordinates robots ).

# Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions

alpha_steps_per_mm 800 # Steps per mm for alpha stepper

beta_steps_per_mm 800 # Steps per mm for beta stepper

gamma_steps_per_mm 800 # Steps per mm for gamma stepper

# Planner module configuration : Look-ahead and acceleration configuration

planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING

acceleration 500 # Acceleration in mm/second/second.

acceleration_ticks_per_second 1000 # Number of times per second the speed is updated

junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters,

# see https://github.com/grbl/grbl/blob/master/planner.c#L409

# and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8

# Lower values mean being more careful, higher values means being

# faster and have more jerk

#minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec

# Stepper module configuration

microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds

minimum_steps_per_minute 1200 # Never step slower than this

base_stepping_frequency 100000 # Base frequency for stepping, higher gives smoother movement

# Cartesian axis speed limits

x_axis_max_speed 1500 # mm/min

y_axis_max_speed 1500 # mm/min

z_axis_max_speed 300 # mm/min

# Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin )

alpha_step_pin 2.0 # Pin for alpha stepper step signal

alpha_dir_pin 0.5! # Pin for alpha stepper direction

alpha_en_pin 0.4 # Pin for alpha enable pin

alpha_current 1.0 # X stepper motor current

alpha_max_rate 1500.0 # mm/min

beta_step_pin 2.1 # Pin for beta stepper step signal

beta_dir_pin 0.11 # Pin for beta stepper direction

beta_en_pin 0.10 # Pin for beta enable

beta_current 1.0 # Y stepper motor current

beta_max_rate 1500.0 # mm/min

gamma_step_pin 2.2 # Pin for gamma stepper step signal

gamma_dir_pin 0.20 # Pin for gamma stepper direction

gamma_en_pin 0.19 # Pin for gamma enable

gamma_current 1.0 # Z stepper motor current

gamma_max_rate 300.0 # mm/min

# Serial communications configuration ( baud rate default to 9600 if undefined )

uart0.baud_rate 115200 # Baud rate for the default hardware serial port

second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface

# and a terminal connected)

#leds_disable true # disable using leds after config loaded

# Extruder module configuration

extruder_module_enable true # Whether to activate the extruder module at all. All configuration

# is ignored if false

extruder_steps_per_mm 140 # Steps per mm for extruder stepper

extruder_default_feed_rate 600 # Default rate ( mm/minute ) for moves where only the extruder moves

extruder_acceleration 500 # Acceleration for retracts, mm/sec^2

extruder_max_speed 1000 # mm/sec NOTE only used for retracts

extruder_step_pin 2.3 # Pin for extruder step signal

extruder_dir_pin 0.22 # Pin for extruder dir signal

extruder_en_pin 0.21 # Pin for extruder enable signal

delta_current 1.5 # Extruder stepper motor current

# Laser module configuration

laser_module_enable false # Whether to activate the laser module at all. All configuration is

# ignored if false.

#laser_module_pin 2.5 # this pin will be PWMed to control the laser. Only P2.0 - P2.5

# can be used since laser requires hardware PWM

#laser_module_max_power 0.8 # this is the maximum duty cycle that will be applied to the laser

#laser_module_tickle_power 0.0 # this duty cycle will be used for travel moves to keep the laser

# active without actually burning

#laser_module_pwm_period 20 # this sets the pwm frequency as the period in microseconds

# Hotend temperature control configuration

temperature_control.hotend.enable true # Whether to activate this ( "hotend" ) module at all.

# All configuration is ignored if false.

temperature_control.hotend.thermistor_pin 0.23 # Pin for the thermistor to read

temperature_control.hotend.heater_pin 2.7 # Pin that controls the heater

temperature_control.hotend.thermistor EPCOS100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64

# for a list of valid thermistor names

temperature_control.hotend.set_m_code 104 #

temperature_control.hotend.set_and_wait_m_code 109 #

temperature_control.hotend.designator T #

#temperature_control.hotend.p_factor 13.7 # permanenetly set the PID values after an auto pid

#temperature_control.hotend.i_factor 0.097 #

#temperature_control.hotend.d_factor 24 #

#temperature_control.hotend.max_pwm 64 # max pwm, 64 is a good value if driving a 12v resistor with 24v.

temperature_control.bed.enable true #

temperature_control.bed.thermistor_pin 0.24 #

temperature_control.bed.heater_pin 2.5 #

temperature_control.bed.thermistor Honeywell100K # see src/modules/tools/temperaturecontrol/TemperatureControl.cpp:64

# for a list of valid thermistor names

temperature_control.bed.set_m_code 140 #

temperature_control.bed.set_and_wait_m_code 190 #

temperature_control.bed.designator B #

#temperature_control.bed.bang_bang false # set to true to use bang bang control rather than PID

#temperature_control.bed.hysteresis 2.0 # set to the temperature in degrees C to use as hysteresis

# when using bang bang

# Switch module for fan control

switch.fan.enable true #

switch.fan.input_on_command M106 #

switch.fan.input_off_command M107 #

switch.fan.output_pin 2.6 #

switch.fan.output_type pwm # pwm output settable with S parameter in the input_on_comand

#switch.fan.max_pwm 255 # set max pwm for the pin default is 255

#switch.misc.enable true #

#switch.misc.input_on_command M42 #

#switch.misc.input_off_command M43 #

#switch.misc.output_pin 2.4 #

#switch.misc.output_type digital # just an on or off pin

# Switch module for spindle control

#switch.spindle.enable false #

# Endstops

endstops_enable true # the endstop module is enabled by default and can be disabled here

#corexy_homing false # set to true if homing on a hbit or corexy

alpha_min_endstop 1.24^! # add a ! to invert if endstop is NO connected to ground

alpha_max_endstop 1.25^ #

alpha_homing_direction home_to_min # or set to home_to_max and set alpha_max

alpha_min 0 # this gets loaded after homing when home_to_min is set

alpha_max 200 # this gets loaded after homing when home_to_max is set

beta_min_endstop 1.26^! #

beta_max_endstop 1.27^ #

beta_homing_direction home_to_min #

beta_min 0 #

beta_max 200 #

gamma_min_endstop 1.28^! #

gamma_max_endstop 1.29^ #

gamma_homing_direction home_to_min #

gamma_min 0 #

gamma_max 200 #

alpha_fast_homing_rate_mm_s 50 # feedrates in mm/second

beta_fast_homing_rate_mm_s 50 # "

gamma_fast_homing_rate_mm_s 4 # "

alpha_slow_homing_rate_mm_s 25 # "

beta_slow_homing_rate_mm_s 25 # "

gamma_slow_homing_rate_mm_s 2 # "

alpha_homing_retract_mm 5 # distance in mm

beta_homing_retract_mm 5 # "

gamma_homing_retract_mm 1 # "

#endstop_debounce_count 100 # uncomment if you get noise on your endstops

# Pause button

pause_button_enable true #

# Panel

panel.enable true # set to true to enable the panel code

panel.encoder_a_pin 3.25!^ # encoder pin

panel.encoder_b_pin 3.26!^ # encoder pin

# Example for reprap discount GLCD

# on glcd EXP1 is to left and EXP2 is to right, pin 1 is bottom left, pin 2 is top left etc.

# +5v is EXP1 pin 10, Gnd is EXP1 pin 9

panel.lcd universal_adapter #

panel.spi_channel 0 # spi channel to use ; GLCD EXP1 Pins 3,5 (MOSI, SCLK)

panel.spi_cs_pin 0.16 # spi chip select ; GLCD EXP1 Pin 4

#panel.encoder_a_pin 3.25!^ # encoder pin ; GLCD EXP2 Pin 3

#panel.encoder_b_pin 3.26!^ # encoder pin ; GLCD EXP2 Pin 5

#panel.click_button_pin 1.30!^ # click button ; GLCD EXP1 Pin 2

#panel.buzz_pin 1.31 # pin for buzzer ; GLCD EXP1 Pin 1

#panel.button_pause_pin 2.11^ # kill/pause ; GLCD EXP2 Pin 8 either

#panel.back_button_pin 2.11!^ # back button ; GLCD EXP2 Pin 8 or

# pins used with other panels

#panel.up_button_pin 0.1! # up button if used

#panel.down_button_pin 0.0! # down button if used

#panel.click_button_pin 0.18! # click button if used

panel.menu_offset 0 # some panels will need 1 here

panel.alpha_jog_feedrate 1000 # x jogging feedrate in mm/min

panel.beta_jog_feedrate 1000 # y jogging feedrate in mm/min

panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min

#panel.hotend_temperature 185 # temp to set hotend when preheat is selected

#panel.bed_temperature 60 # temp to set bed when preheat is selected

# Example of a custom menu entry, which will show up in the Custom entry.

# NOTE _ gets converted to space in the menu and commands, | is used to separate multiple commands

custom_menu.power_on.enable true #

custom_menu.power_on.name Power_on #

custom_menu.power_on.command M80 #

custom_menu.power_off.enable true #

custom_menu.power_off.name Power_off #

custom_menu.power_off.command M81 #

# Only needed on a smoothieboard

currentcontrol_module_enable true #

return_error_on_unhandled_gcode false #

# network settings

network.enable true

# enable the ethernet network services

network.webserver.enable true # enable the webserver

network.telnet.enable true # enable the telnet server

#network.ip_address auto # use dhcp to get ip address

# uncomment the 3 below to manually setup ip address

network.ip_address 192.168.178.222 # the IP address

network.ip_mask 255.255.254.0 # the ip mask

network.ip_gateway 192.168.178.1 # the gateway address

#network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict

#

#

#

Configuration after adding support for auto-homing on 2023-09-17

# NOTE Lines must not exceed 132 characters

# Robot module configurations : general handling of movement G-codes and slicing into moves

default_feed_rate 200 # Default rate ( mm/minute ) for G1/G2/G3 moves

default_seek_rate 1500 # Default rate ( mm/minute ) for G0 moves

mm_per_arc_segment 0.5 # Arcs are cut into segments ( lines ), this is the length for

# these segments. Smaller values mean more resolution,

# higher values mean faster computation

mm_per_line_segment 5 # Lines can be cut into segments ( not usefull with cartesian

# coordinates robots ).

# Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions

alpha_steps_per_mm 800 # Steps per mm for alpha stepper

beta_steps_per_mm 800 # Steps per mm for beta stepper

gamma_steps_per_mm 800 # Steps per mm for gamma stepper

# Planner module configuration : Look-ahead and acceleration configuration

planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING

acceleration 500 # Acceleration in mm/second/second.

acceleration_ticks_per_second 1000 # Number of times per second the speed is updated

junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters,

# see https://github.com/grbl/grbl/blob/master/planner.c#L409

# and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8

# Lower values mean being more careful, higher values means being

# faster and have more jerk

#minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec

# Stepper module configuration

microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds

minimum_steps_per_minute 1200 # Never step slower than this

base_stepping_frequency 100000 # Base frequency for stepping, higher gives smoother movement

# Cartesian axis speed limits

x_axis_max_speed 2000 # mm/min

y_axis_max_speed 2000 # mm/min

z_axis_max_speed 1000 # mm/min

# Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin )

alpha_step_pin 2.0 # Pin for alpha stepper step signal

alpha_dir_pin 0.5! # Pin for alpha stepper direction

alpha_en_pin 0.4 # Pin for alpha enable pin

alpha_current 1.0 # X stepper motor current

alpha_max_rate 2000.0 # mm/min

beta_step_pin 2.1 # Pin for beta stepper step signal

beta_dir_pin 0.11 # Pin for beta stepper direction

beta_en_pin 0.10 # Pin for beta enable

beta_current 1.5 # Y stepper motor current

beta_max_rate 2000.0 # mm/min

gamma_step_pin 2.2 # Pin for gamma stepper step signal

gamma_dir_pin 0.20 # Pin for gamma stepper direction

gamma_en_pin 0.19 # Pin for gamma enable

gamma_current 1.0 # Z stepper motor current

gamma_max_rate 1000.0 # mm/min

# Serial communications configuration ( baud rate default to 9600 if undefined )

uart0.baud_rate 115200 # Baud rate for the default hardware serial port

second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface

# and a terminal connected)

#leds_disable true # disable using leds after config loaded

# Extruder module configuration

extruder_module_enable false # Whether to activate the extruder module at all. All configuration

# is ignored if false

# Laser module configuration

laser_module_enable false # Whether to activate the laser module at all. All configuration is

# ignored if false.

#laser_module_pin 2.5 # this pin will be PWMed to control the laser. Only P2.0 - P2.5

# can be used since laser requires hardware PWM

#laser_module_max_power 0.8 # this is the maximum duty cycle that will be applied to the laser

#laser_module_tickle_power 0.0 # this duty cycle will be used for travel moves to keep the laser

# active without actually burning

#laser_module_pwm_period 20 # this sets the pwm frequency as the period in microseconds

# Hotend temperature control configuration

temperature_control.hotend.enable false # Whether to activate this ( "hotend" ) module at all.

# All configuration is ignored if false.

temperature_control.bed.enable false #

# Switch module for fan control

switch.fan.enable false #

# Switch module for spindle control

#switch.spindle.enable false #

# Endstops

endstops_enable true # the endstop module is enabled by default and can be disabled here

#corexy_homing false # set to true if homing on a hbit or corexy

alpha_min_endstop 1.24^ # add a ! to invert if endstop is NO connected to ground

alpha_max_endstop 1.25^ #

alpha_homing_direction home_to_min # or set to home_to_max and set alpha_max

alpha_min 0 # this gets loaded after homing when home_to_min is set

alpha_max 200 # this gets loaded after homing when home_to_max is set

alpha_limit_enable false

beta_min_endstop 1.26^ #

beta_max_endstop 1.27^ #

beta_homing_direction home_to_min #

beta_min 0 #

beta_max 200 #

beta_limit_enable false

gamma_min_endstop 1.28^ #

gamma_max_endstop 1.29^ #

gamma_homing_direction home_to_max #

gamma_min 0 #

gamma_max 100 #

gamma_limit_enable false

alpha_fast_homing_rate_mm_s 100 # feedrates in mm/second

beta_fast_homing_rate_mm_s 100 # "

gamma_fast_homing_rate_mm_s 20 # "

alpha_slow_homing_rate_mm_s 25 # "

beta_slow_homing_rate_mm_s 25 # "

gamma_slow_homing_rate_mm_s 2 # "

alpha_homing_retract_mm 5 # distance in mm

beta_homing_retract_mm 5 # "

gamma_homing_retract_mm 1 # "

home_z_first true

#endstop_debounce_count 100 # uncomment if you get noise on your endstops

# Pause button

pause_button_enable true #

# Only needed on a smoothieboard

currentcontrol_module_enable true #

return_error_on_unhandled_gcode false #

# network settings

network.enable true

# enable the ethernet network services

network.webserver.enable true # enable the webserver

network.telnet.enable true # enable the telnet server

#network.ip_address auto # use dhcp to get ip address

# uncomment the 3 below to manually setup ip address

network.ip_address 192.168.178.222 # the IP address

network.ip_mask 255.255.254.0 # the ip mask

network.ip_gateway 192.168.178.1 # the gateway address

#network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict

Workflow

- Model (CAD)

- Erzeugen des Models mittels einer CAD-Software.

- Fräsanweisungen (CAM)

- Erzeugen der Fräsanweisungen/Maschinenanweisungen mit einer CAM.

- Wir suchen noch nach einer brauchbaren Open-Source Lösung.

- CamBam (kommerziell, Windows): Es gibt eine ältere Mono Version für Linux. Die Demo schneidet nach 40 mal Starten Gcode ab.

- CamBam ist auf Stratux installiert

- FreeCAD mit Path Workbench (Vortrag dazu)

- PyCAM (open source, plattformunabhängig): Sieht im Vergleich zu aktuellen kommerziellen Lösungen alt aus und ist bisweilen recht langsam.

- HeeksCAD (open source, Windows/Linux):

- Inventor HSM (kommerziell, Windows 64bit): Gibt für Studenten eine 3-Jahres Lizenz kostenlos, aber mit viel DRM.

- FlatCam Tool zur Generierung von Maschinencode für das CNC-Fräse/Isolationsfräsen.

- jscut, SVG nach GCode, läuft im Browser, Open Source auf GitHub

- Inkscape mit GCodetools-Plugin (Tutorial)

- Eigenbau by Drahflow Python-Script für Umwandlung von Tiefenkarten in G-Code.

- Simulation

- Eine Simulation der Fräsanweisungen kann bei Bedarf mit CAMotics durchgeführt werden

- Kleinere G-Code Dateien simuliert auch http://nraynaud.github.io/webgcode/

- Übertragen auf CNC-Controller Smoothieboard

- Per Dateiupload (Datenträger von Smoothieboard, SD-Karte) SmoothieControl

- notfalls kann man das SmoothieBoard auch über USB mit dem Befehl

netin Pronterface oder über die serielle Konsole nach seiner IP-Adresse fragen

- notfalls kann man das SmoothieBoard auch über USB mit dem Befehl

- Per Dateiupload (Datenträger von Smoothieboard, SD-Karte) SmoothieControl

- Koordinatensystem der Fräse setzen

- Fräse per Smoothie WebApp auf den gewünschten Nullpunkt fahren

- per Webapp den G-Code "G92 X0 Y0 Z0" senden (Setzt aktuelle Position als X:0, Y:0, Z:0 im globalen Koordinatensystem.)

- Fräsen

Parameter für verschiedene Werkstoffe

Parameter finden sich sind auf der Unterseite CNC-Fräse/Parameter

Steuern des Smoothieboards

- Per seriell Verbindung über Konsole "screen /dev/ttyACM0 115200", oder Pronterface GUI

- Per Netzwerkverbindung über Konsole mit Telnet, oder Http Web UI

- Mittlerweile existiert sogar eine Android App SmoothieControl

- bCNC ermöglicht das Senden von GCODE-Anweisungen und Visualisierung der Fräsbahnen in einer GUI.